PRODUCTS

A company that cares about people and the environment and cherishes the value of the future,

along with PRIME SEAL

- HOME

- Products

- SPIRAL WOUND GASKET

SPIRAL WOUND GASKET

Product Feature

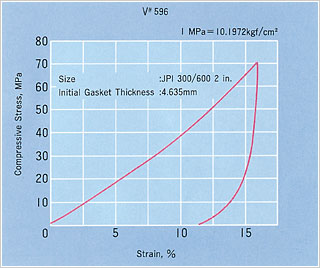

Spiral wound gasket is a high performance semi-metallic gasket reasonably designed for high temperature/high pressure. It has high elasticity and its tightening strength can be controlled by mounting thickness; therefore it is widely used not only for thermal or nuclear power stations and steam turbine thermo-mechanical devices but also process line or heat transfer fluid line in petroleum refining or petrochemical industry.

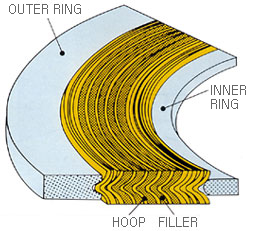

This type of gasket is made in spiral shape rolled up tightly by overlapping the filler selected by hoop of V-shape section and specifications and fixed with spot welding at the start and end part of the hoop. For proper fitting for the concerned flange, inner/outer ring or partition should be attached.

Product Types

| Product | Product No. |

Features | Comparison |

|---|---|---|---|

|

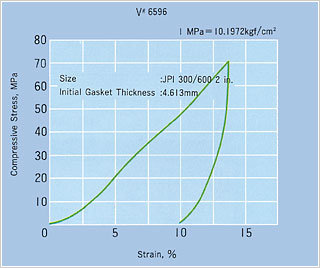

V#6590 V#6591 V#6592 V#6596 |

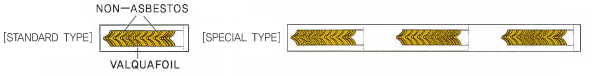

These are the fillers of ValquaFoil |

|

|

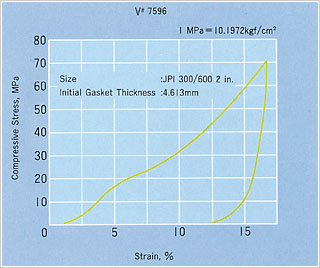

V#7590 V#7591 V#7592 V#7596 |

These are the fillers of Valflon |

|

|

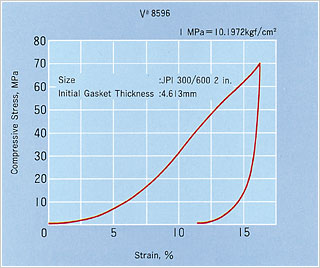

V#8590 V#8591 V#8592 V#8596 |

These are the fillers of Non-As |

|

|

V#8590L V#8591L V#8592L V#8596L |

These are the fillers of Non-As ValquaFoil |

|

|

|||

|

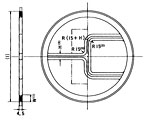

V#─Y | It has a metal jacket type partition inside the spiral wound gasket. It is a high performance gasket for multi-tube heat exchangers; it is safe to use in frequent temperature change or severe temperature/pressure condition. | |

| V#─S |

It is a releasing gasket used in manholes/handholes of boilers and bonnet part of valves. There are various shapes such as obround, oval, diamond, square and pear and the shapes shown below are the most widely used.

|

||

Criteria for Gasket Selection

Gasket Types and Suitability of the Gaskets’ Placement

FLANGE FACINGS GASKETS |

|

|

|

|

|---|---|---|---|---|

|

○ | △ | ─ | ─ |

|

○ | △ | ─ | ─ |

|

─ | ─ | △ | ○ |

|

─ | ─ | ○ | △ |

| * Note | ○ : Applied | △ : Applied if necessary | ─ : Not applied |